pgm rod and ball mills

Ball Mills vs Rod Mills - 911Metallurgist

2017年7月3日 Rod Mills = Selective Grinding. Ball Mills = Non-Selective Grinding. Large Balls Small Rods Compared. Is it better to use a grinding mill with large balls or will small rods? How

[خذ المزيد]

BALL TUBE AND ROD MILLS, Rose And Sullivan 2

2021年2月9日 This book throws new light on the internal mechanics of mills. It covers among others the following aspects: Ball, tube, rod, pebble, batch, grate-discharge, trunnion-overf1ow, hardinage and airswept mills; open- and closed

[خذ المزيد]

A Review of the Grinding Media in Ball Mills for Mineral Processing

2023年10月27日 The grinding media impart the forces required for size reduction and determine the category of tumbling mills: autogenous, rod mills and ball mills. Autogenous and semi

[خذ المزيد]

Simulating large-diameter industrial ball mills from batch-grinding ...

2024年1月1日 The work demonstrates the calibration of industrial-scale ball mill model parameters from laboratory milling tests on Platinum Group Metals (PGM) and Itabirite iron

[خذ المزيد]

Rod and Ball Mills (d7a19c4a-b72b-4e31-abb4-bdb037d4fa45)

1998年1月1日 Rod and ball mills essentially draw constant power, thus are well suited for use of synchronous motors with power factor correction capabilities as drive motors. A net of

[خذ المزيد]

Rod and Ball Mills - OneMine

This chapter covers rod and ball mills which utilize manufactured metallic grinding media. Fig. 1 shows the cross section of an overflow rod mill, Fig. 2 an overflow ball mill, and Fig. 3 a

[خذ المزيد]

The Extractive Metallurgy of South Africa’s Platinum Ores

This article will review advances in PGM extrac-tion, including developments in semi-autog-enous and fully autogenous milling; flota-tion equipment applications for treating high-chrome ores;

[خذ المزيد]

OVERVIEW OF PGM PROCESSING - Anglo American Platinum

Platinum Group Metals (PGMs) are recovered through underground and open pit mining from poly-metallic sulphide ores containing PGMs, Nickel, Copper and other metals: Platinum (Pt),

[خذ المزيد]

TUMBLING MILL MECHANICS

A tumbling mill is a collective name for the generally known ball mills, rod mills, tube mills, pebble mills and autogeneous mills. For all these kinds of mills the mechanics can be dealt with

[خذ المزيد]

_Taurus - Ball Mill - NETZSCH Grinding Dispersing

NETZSCH Taurus Ball Mill, the pinnacle of fine and ultra-fine grinding technology. Achieve precise particle sizes with durable, low-maintenance equipment.

[خذ المزيد]

RoM BALL MILLS - A COMPARISON WITH AG/SAG MILLING

RoM Ball mills, like SAG mills, utilise coarse rocks in the RoM feed as grinding media but with 25 – 40% steel balls added, which is advantageous when the coarse fraction in the RoM feed is ...

[خذ المزيد]

Replacement of Wet Ball Milling with High-Pressure Grinding

2023年11月28日 CMM ore was ground in a rod mill, as is common before flotation testing, and PGM ore was ground in a ball mill, as is common before leach testing. The plant cyclone overflows could not be used for such purposes because of gravity gold recovery in the grinding circuit at PGM, and because of CMM flotation feed (cyclone overflow) sample aging.

[خذ المزيد]

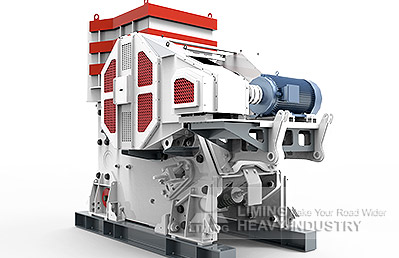

Selection of Rod Mills, Ball Mills and Regrinding Mills

Selection of Rod Mills, Ball Mills and Regrinding Mills - Free download as PDF File (.pdf), Text File (.txt) or read online for free. This document discusses factors to consider when choosing an ore feeder for a beneficiation plant. It outlines

[خذ المزيد]

A Review of the Grinding Media in Ball Mills for Mineral

2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles. Grinding media play an important role in the comminution of mineral ores in these mills. This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the mass loss, as

[خذ المزيد]

The extractive metallurgy of South Africa's platinum ores

This article will review advances in PGM extraction, ... crushing, and ball milling was used initially to treat the. ... where the primary comminution stage uses a rod mill.

[خذ المزيد]

Ball Mill PPT - SlideShare

2015年11月30日 A ball mill consists of a hollow cylindrical shell that rotates about its axis, with balls occupying 30-50% of the volume to facilitate grinding as the shell rotates. Applications of ball mills include grinding metallic powders, carbon, coal, cement, fertilizers and other materials. Read less

[خذ المزيد]

A Review of the Grinding Media in Ball Mills for Mineral Processing

2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles. Grinding media play an important role in the comminution of mineral ...

[خذ المزيد]

PGM Platinum Mining Extraction - 911Metallurgist

2016年2月16日 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise. PGM Platinum Mining Extraction

[خذ المزيد]

Rod and Ball Mills - OneMine

This chapter covers rod and ball mills which utilize manufactured metallic grinding media. Fig. 1 shows the cross section of an overflow rod mill, Fig. 2 an overflow ball mill, and Fig. 3 a diaphragm (grate) discharge ball mill. This website uses cookies to ensure you get the best user experience you agree to our website's User Agreement.

[خذ المزيد]

Ball Mill vs Rod Mill: Which is the Best for Your Mining Operation

Ball mills and rod mills are two types of grinding mills that are often used for this purpose. Both types of mills have their advantages and disadvantages, and the choice between the two depends on several factors. Ball Mills: Ball mills are cylindrical devices used to grind materials such as chemicals, ores, and paints.The cylinder is filled with a grinding medium (such as steel balls)

[خذ المزيد]

Ball mill PPT Free Download - SlideShare

2015年4月24日 2. Ball mill consist of a hollow cylindrical shell rotating about its axis. Axis of the shell horizontal or at small angle to the horizontal It is partially filled with balls made up of Steel,Stainless steel or rubber Inner surface of the

[خذ المزيد]

(PDF) Effects of high pressure grinding rolls on ... - ResearchGate

2010年1月1日 HPGR prior to rod milling was actually to the detriment of the flo-tation performance (Palm et al., 2010a). ... the ball mill product had the best PGM liberation, the final PGE.

[خذ المزيد]

What is the Difference Between Tumbling Mill and Ball Mill?

Rod mills are similar to ball mills but use long rods for grinding media. Autogenous mills are self-grinding mills that use the ore itself as grinding media. C. Advantages and Disadvantages. Tumbling mills offer several advantages, including high

[خذ المزيد]

Rod and Ball Mill

Ball/Rod mill Literature . The Ball/Rod mills are meant for producing fine particle size reduction through attrition and compressive forces at the grain size level. They are the most effective laboratory mills for batch-wise, rapid grinding of medium-hard to

[خذ المزيد]

Fine grinding: How mill type affects particle shape characteristics

2017年9月1日 In Fig. 9, the stirred mill ultrafine grind initially appears to have a considerably higher combined PGM – BMS liberation than the ball mill, ... A comparison of particle bed breakage and rod mill grinding with regard to mineral liberation and particle shape effects. Miner. Eng., 11 (1998) ...

[خذ المزيد]

Replacement of Wet Ball Milling with High-Pressure Grinding

2023年11月28日 CMM ore was ground in a rod mill, as is common before flotation testing, and PGM ore was ground in a ball mill, as is common before leach testing. The plant cyclone overflows could not be used for such purposes because of gravity gold recovery in the grinding circuit at PGM, and because of CMM flotation feed (cyclone overflow) sample aging.

[خذ المزيد]

Keys to best practice comminution - ScienceDirect

2022年4月1日 In those days, 3 stages of crushing, and rod and ball mill grinding, were common in comminution flowsheets. Bond’s Rod Mill Work Index (RM Wi) and Ball Mill Work Index (BM Wi) tests provided good designs for grinding mills. If the design was 1200 t/d, each stage had to be able to produce 1200 t/d or (54 t/h at 92.6% availability).

[خذ المزيد]

Trunnion Bearing Assembly Ball Mill Rod Mill - 911Metallurgist

2015年7月28日 It is the TRUNNION LINER, it fits inside the bearing to protect it from wear caused by the ore being washed over the liner and through the bearing as it is fed to or discharged from the mill. Ball Mill TRUNNION BEARINGS. Swivel type lead-bronze bushed trunnion bearings are generally furnished on large diameter ball Mills.

[خذ المزيد]

(PDF) Energy Efficient Ball Mill Circuit – Equipment Sizing ...

2013年7月15日 PDF The ball mill in closed circuit with hydrocyclones is an industry standard, ... equipment other than three stage crushing circuit or rod mill. Morrell’s methodology (Morrell, 2004a, ...

[خذ المزيد]

Hammer mill and Ball mill PPT Free Download - SlideShare

2021年1月12日 It describes the hammer mill and ball mill, which use mechanical forces for size reduction. The hammer mill works by impact between rapidly moving hammers and powder materials, while the ball mill uses impact and attrition between rapidly moving balls inside a rotating cylinder.

[خذ المزيد]- التعلم تصميم المسمار الناقل

- الحجر qarry كسارة مصر

- عملية تعدين الحديد الأساسية

- طحن استخدام مصنع عجلة

- قائمة محطات الفحم

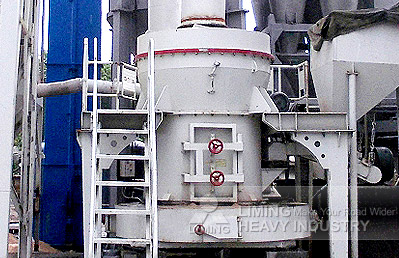

- روسيا مطحنة عمودية

- آلة طحن الحجر الجيري في كوريا

- الكرتون على مطحنة Posho

- من مخروط محطم العمل

- حار بيع تشنغمينغ تأثير محطم

- سنگ شکن سنگ شکن تالک و یا تالک

- صغيرة كسارة الدليميت للبيع في إندونيسيا

- كيفية استبدال الطوق والعتاد في مطحنة الكرة

- آلة كسارة هوراي كاليفورنيا

- المصنعين آلة كسارة الحجر في ألمانيا

- هو الحجر الجيري المستخدمة في إنتاج الحديد الإسفنج

- نظام التروس في مطحنة طحن للتحليل

- سازنده دستگاه کارخانه پردازش ادویه

- تصميم كسارة لخام النحاس

- العزوم المؤثرة على الأعمدة تصميم يدوي

- مجموعة واسعة حجر محطم

- كسارة الجبس للبيع في الإمارات العربية المتحدة

- 20 لهجة كسارة للبيع في المملكة العربية السعودية

- مطحنة الأسمنت طحن الأسمنت

- الفك كسارات و كوماتسو مخروط

- تعدين ملح الصخور في ألمانيا

- ضررا من تفتيت الحصوات

- معدات ثقيلة عملاقة يوت يوب

- أضواء التعدين المعتمدة من مشا

- كسارة الفك هارجا 400x600

© Copyright - PETER&X محطم