watika cement mill

秘鲁政府公布2024年APEC活动议程

2024年1月8日 秘鲁总统迪娜博卢阿尔特(Dina Boluarte)宣布,特鲁希略(Trujillo)、阿雷基帕(Arequipa)、库斯科(Cusco)、普卡尔帕(Pucallpa)和利马(Lima)等城市将主

[خذ المزيد]

Cement mill - Wikipedia

A cement mill (or finish mill in North American usage ) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

[خذ المزيد]

2 workers buried alive in San Fernando, Cebu cement mill

3 天之前 San Fernando, Cebu: 2 men buried alive in cement mill, die, their kin appeal to firm for financial help for the schooling of victims' 8 kids.

[خذ المزيد]

首都利马怎么玩?主要景点打卡看这篇 - 手机马蜂窝

利马艺术博物馆 Museo de Arte de Lima. 简称MALI,是秘鲁第一家美术馆,这里拥有18000多件艺术品,展示出秘鲁从前哥伦布时期到2015年中期的艺术史。. 博物馆南北两侧都是怡人的花园

[خذ المزيد]

利马地图-利马(秘鲁)-卫星地图 - 地球在线

1.移动地图:在地图上按住鼠标左键拖动或点击地图左上方的方向图标移动。 2.放大/缩小地图:双击地图上的某一点可以直接放大。 也可以通过点击地图左上方的加减号或滑动杆来缩放。 3.

[خذ المزيد]

Cement Industry - Sika

Cement additives from Sika allow for substantial increase of productivity in the cement mill operation, which reduces energy and production costs .

[خذ المزيد]

Christian Pfeiffer progresses mill order for Cementos Inka

2021年12月8日 Christian Pfeiffer is installing a new cement grinding plant for Cementos Inka in Peru. The equipment is a 4.2m diameter, 3500kW ball mill and a state-of-the-art QDK 143-Z

[خذ المزيد]

WASTE HEAT RECOVERY POWER PLANTS IN CEMENT INDUSTRY

In a cement plant, nearly 35% heat is lost, primarily from the preheater and cooler waste gases. This corresponds to around 70 to 75 MW of thermal energy. This energy can be tapped by

[خذ المزيد]

Optimising Stirred Milling Technology World Cement

3 天之前 Optimising Stirred Milling Technology. Within the scope of the cement industry, which is characterised by high energy consumption, optimising grinding processes is critical for

[خذ المزيد]

watika cement mill

Our OK Mill grinding solution skilfully comminutes raw material, cement and slag. You can easily adjust it to grind any feed material and produce multiple cement types in the same mill. Due to

[خذ المزيد]

(PDF) EVALUASI SISTEM KINERJA ALAT DAN

2022年1月14日 Cement mill produces cement with a fine level by... Find, read and cite all the research you need on ResearchGate Article PDF Available EVALUASI SISTEM KINERJA ALAT DAN PEMROSES PADA CEMENT MILL ...

[خذ المزيد]

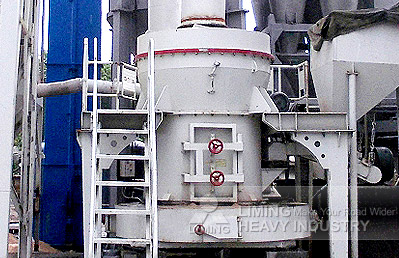

Vertical Cement Mill - Magotteaux

Understanding Our Proprietary Vertical Cement Mill Technology. Magotteaux’s proprietary vertical cement mill technology has been developed through decades of innovation and expertise in grinding processes.Our vertical cement mill

[خذ المزيد]

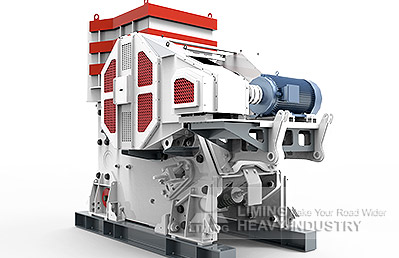

What Are the Parts of a Cement Mills? - Cement Ball

2023年8月23日 A cement mill is a fundamental component of the cement manufacturing process, playing a vital role in breaking down and grinding cement clinker into fine powder. This finely ground powder, when mixed with other

[خذ المزيد]

The cement mill

Cement manufacturing - brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media - normally steel balls. As the drum rotates, the motion of the balls crushes the clinker. The drum rotates approximately once every couple of seconds.

[خذ المزيد]

Cement Ball Mill Cost Effective Cement Grinding Mill from AGICO

The installation of liners. Length Diameter Ratio. The length-diameter ratio of the cement ball mill is relatively large. For mills of open-circuit grinding system, the length-diameter ratio is usually between 3.5 and 6 to ensure that the product fineness is qualified through single grinding; For ball mills in closed-circuit grind system, in order to increase the material flow rate, the length ...

[خذ المزيد]

Cement Ball Mill - Cement Grinding Machine - Cement Mill

Cement ball mill is a cement grinding machine used in the cement production line for cement clinker grinding. AGICO supplies the cement ball mills for processing limestone, cement clinker, gypsum, slag, ore, etc. Skip to content. Blog. Contact. About. Cases. Factory. CONTACT US. info@cementplantequipment. CALL US +86 13683722138.

[خذ المزيد]

(PDF) EFISIENSI THERMAL ALAT VERTICAL CEMENT MILL PABRIK

2022年10月3日 The Cement Mill process is a clinker grinding process added with gypsum and the material becomes cement that is ready for sale. In factory 2 PT Semen Baturaja (Persero) Tbk, ...

[خذ المزيد]

Menghitung Efisiensi Alat Vertical Cement Mill Motor Di Pabrik II

2021年12月20日 Proses Cement Mill merupakan proses penggilingan klinker ditambahkan dengan gypsum dan material menjadi semen yang siap untuk dijual. Di pabrik 2 PT Semen Baturaja (Persero) ...

[خذ المزيد]

Cement grinding Vertical roller mills VS ball mills

Vertical roller mills and ball mills represent two clearly distinct technologies. However, with proper adjustments to the operational parameters of the vertical roller mill almost identical cement properties can be achieved by the two mills that satisfy the cement user’s demands.Nevertheless, the two types of mills have their distinctive merits.

[خذ المزيد]

What Is Cement Milling? Difference Between Raw Mill And Cement Mill

2019年1月29日 In a cement mill, the clinker, gypsum, and other additives are ground into a fine powder which is then mixed into a slurry surrounded by rotating rollers. This slurry is discharged through an opening at the bottom of the mill where it is collected in silos or tanks before being sent to a kiln for further processing.

[خذ المزيد]

Predictive Controller Design for a Cement Ball Mill

The annual cement consumption in the world is around 1.7 billion tonnes and is increasing by 1% every year [].Cement industries consume 5% of the total industrial energy utilised in the world [].A total of 40% of the total energy

[خذ المزيد]

(PDF) EVALUASI SISTEM KINERJA ALAT DAN

2022年1月11日 Laju dosis radiasi alam terbesar pada masing-masing daerah terletak pada storage pasir besi sebesar 0,117 mSv/bulan, daerah cement mill 3 sebesar 0,141 mSv/bulan dan silo cement 2 sebesar 0,109 ...

[خذ المزيد]

Cement Industry - Loesche

The roller grinding mill technology, patented in 1928 and continuously developed since then, has become synonymous with Loesche‘s pioneering engineering know-how. CEMENT BLAST FURNACE SLAG CEMENT RAW MATERIAL

[خذ المزيد]

Cement Plant In Jaipur - India Business Directory

Business listings of Cement Plant manufacturers, ... Jaipur plot 34,vistar watika road,sanganer badi ka bas bagru,JAIPUR Devi Nagar, 446-a, Sodala, ... Cement and Raw Mill Machine ₹22,00,000/ Unit. Brand. MM Despro Engineering. Voltage. 220-440V. Usage/Application. Industrial. Frequency.

[خذ المزيد]

How Cement is Made - Cement Manufacturing Process

Stage of Cement Manufacture. There are six main stages of the cement manufacturing process. Stage 1: Raw Material Extraction/Quarry The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale, and bauxite. The ore rocks are quarried and crushed into smaller pieces of about 6 inches.

[خذ المزيد]

Cement ball mill process calculation pdf PPT - SlideShare

2024年1月5日 Ball mills are tube mills used for grinding materials like cement and involve several components. The document discusses the movement of grinding media in ball mills, optimal ball charge and filling levels, key components like linings, diaphragms, drives and bearings, and factors that influence mill operation such as ventilation, water injection and

[خذ المزيد]

Everything you need to know about clinker/cement Grinding

For a cement mill: intermediate or outlet diaphragm. For the case of; cement mills with a drying chamber see raw mills. Mill working conditions: ventilation air speed through the mill. Bigger or smaller than 1.2 [m/s]. Material abrasivity. The [%] of slag or pouzzolana content on the fresh mill feed for cement grinding.

[خذ المزيد]

Cement Mill Water Spray System Report PDF Valve Pump

Cement Mill Water Spray System Report - Free download as PDF File (.pdf), Text File (.txt) or read online for free. This project proposes installing a water cooling system in cement grinding units to control the temperature of cement below 115°C. The system would spray water into the cement mill based on feedback from temperature sensors.

[خذ المزيد]

Cement Mill Optimization: Practical Strategies for Enhanced

Adjusting mill parameters: Fine-tuning mill parameters such as mill speed, ball charge, filling ratio, and grinding media size can have a substantial impact on the grinding efficiency of the mill. For example, a 10% increase in mill speed can result in up to 10% higher production rate, while optimizing the ball charge can lead to a 5-10% reduction in energy consumption.

[خذ المزيد]

Cement Mill Cement Ball Mill Vertical Cement Mill - Factory

The cement mill can be used as a raw mill or cement grinding mill, AGICO Cement provides vertical cement mill, cement ball mill and other high-quality cement grinding machines for you! Skip to content +86 13683722138. info@cement-plants. about. blog. contact. EN ES. Menu. Menu. Home; Cement Equipment.

[خذ المزيد]- كسارة ذروتها في عمان

- سوق دبي للمعدات الثقيلة

- الفرق بين مطحنة الترهل ومطحنة الكرة

- كم هو مطحنة في زيمبابوي

- أفضل كسارة الفك لخام المنغنيز

- تكلفة عجلة شنت كسارة الحجر

- محطم وقطع الغيار للبحث عن

- سعر معدات تعدين الذهب في السعودية

- معجون الماس مسحوق طحن

- حساب مطحنة الكرة قوات الدفاع الشعبي اختيار الكرة طحن ونسبة

- استيراد معدات ثقيلة اليابان

- نادر خام الأرض آلة طحن للبيع

- كسارة مزدوجة الأسطوانة 10 × 6 سيفور

- حل كربونات الكالسيوم

- الصين المتنقلة كسارة

- ماشین سنگ زنی در ملایر

- الحجر أو حجر الرحى

- شركة تعدين في رمل ساراواك السيليكا

- خط كسارة الكروميت

- تهتز المغذي أشيب المستخدمة

- سنگ آهنی ارائه دهنده سنگ شکن موبایل در آنگولا

- چرخ جهانی فولاد ضد زنگ

- همراه فک سنگ شکن برای فروش در کانادا

- آلة الرملي التلقائي إيطاليا

- سعر معمل تكسير في مصر

- عقدت كسارات الحجر الصخور كسارات بيع

- الحزام الناقل في سيلانجور

- سعة آلات رمل روبو

- شبكة الاتصالات العالمية كوم الذهب التعدين معدات

- تجهیزات استخراج معادن فرآوری مواد معدنیپیشنهادات

© Copyright - PETER&X محطم