grinding mill maintenance

Mill maintenance – 3 simple ways to keep your mill at its best

2017年12月19日 With the grinding mill critical to a plant’s throughput, it pays to ensure mills receive the necessary care and maintenance. Too often mill maintenance is reactive, occurring due to a breakdown. The result is higher repair costs as resources are rushed to site, as well

[خذ المزيد]

Material Use Roller Mill Maintenance: What You

2023年7月25日 Roller mill maintenance is crucial to optimizing performance, and minimizing downtime. Part of properly maintaining your machinery is understanding how different products can affect the roller mill, and how the

[خذ المزيد]

Ball Mill Maintenance Installation Procedure

2016年10月20日 It has been found that concrete foundations on a weight basis should be at least 1½ times the total weight of the grinding mill with its

[خذ المزيد]

Predictive maintenance in mining industry: grinding mill case study ...

2022年1月1日 The maintenance of industrial mining machines is a challenging process, especially in the case of critical assets, as it impact the hole process: for instance the grinding

[خذ المزيد]

Milling Operations: Reviewing maintenance strategies

2022年5月30日 The primary mill maintenance goal should be to ensure the milling asset is available for operation 100% of planned operating time (100% reliability). Every piece of equipment is important and can put the mill down or

[خذ المزيد]

Maintenance reliability planning AssetCare for grinding mills

maintenance costs. It provides a structured and organized approach to ensure that equipment assets are managed in a way that aligns with the organization’s objectives and supports long

[خذ المزيد]

Managing Mill Maintenance - Roller Mill Maintenance PDF Mill ...

key concern for all millers is getting maximum life and efficiency out of equipment while maintaining a high standard of product. Roller mills play a key part in the milling process and

[خذ المزيد]

Mill Maintenance Plan: 3 Steps That Maximize Mill

2014年7月15日 Like any other piece of machinery, grinding mills will break down but through a proper maintenance plan, problems can be spotted early thus saving dollars, stress and valuable man-hours. So what makes for an effective

[خذ المزيد]

Innovative predictive maintenance for mining grinding mills: from

2024年10月8日 This article presents an innovative predictive maintenance for grinding mills, aiming to enhance operational efficiency and minimize downtime. Leveraging advancements

[خذ المزيد]

Mill Maintenance Plan: 3 Steps That Maximize Mill

2014年7月15日 In truth, regular maintenance is as vital as the grinding mill machine itself, but to get the very most from it, a dedicated maintenance plan is recommended. There are several reasons why a maintenance plan works

[خذ المزيد]

Ball Mill Maintenance Process and Methods - Mining-pedia

2023年7月18日 When maintaining the ball mill, the following tools and equipment may be helpful: 1. Wrench: used to disassemble and install fastening bolts, nuts, and other components.. 2. Lubricating oil gun: used to add lubricating oil to bearings, gears, transmission devices, and other parts.. 3. Lubricating oil: selecting appropriate lubricating oil is crucial for ball mill

[خذ المزيد]

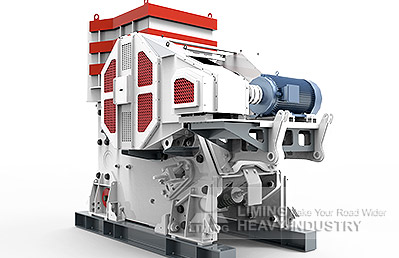

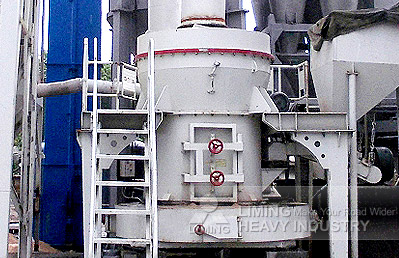

Stone Crushers, Mill and Grinding

5X Series Pendulum Roller Grinding Mill is new mature and advanced equipment. READ MORE. GF Vibrating Feeder. ... Appointment A Company Involved In Service And Maintenance. Quick response, Liming Heavy Industry welcomes

[خذ المزيد]

Managing Mill Maintenance - Roller Mill Maintenance PDF Mill ...

Managing mill maintenance - Roller mill maintenance - Free download as PDF File (.pdf), Text File (.txt) or read online for free. A key concern for all millers is getting maximum life and efficiency out of equipment while maintaining a high standard of product. Roller mills play a key part in the milling process and have a direct influence on subsequent processes and eventually on the

[خذ المزيد]

Taking your grinding to the next level Mill lining solutions for ...

The value of data lies in how it is used. Even if you discover the most incredible insights in your grinding process data, they won’t matter unless they are actionable. These actions then increase maintenance efficiency, improve availability, lower maintenance costs and help you reach your sustainability targets. Using data to your benefit 12

[خذ المزيد]

Optimizing Maintenance Practices for Raw Vertical Roller Mills

2024年3月11日 Effective maintenance of these VRMs is essential to ensure uninterrupted operation, maximize throughput, and minimize downtime. ... The burnt coke processing project includes three sets of MTW European type grinding mill

[خذ المزيد]

Grinding mills SKF

SKF offers solutions for autogenous mills, ball mills, high pressure grinding rolls, rod mills, SAG mils and horizontal grinding mills. The solutions are designed to protect pinions and trunnions and prevent failure in these harsh operating conditions – helping you improve reliability and safety while reducing maintenance and operating costs.

[خذ المزيد]

Rod Mill Maintenance: Tips for Longevity and Performance

2024年10月30日 Before diving into maintenance tips, it's crucial to understand why maintenance is essential for rod mills. Proper maintenance not only extends the life of the equipment but also optimizes its performance, resulting in increased productivity and reduced operational costs. Here are a few reasons why rod mill maintenance should be a priority: 1.

[خذ المزيد]

Innovative predictive maintenance for mining grinding mills:

2024年10月8日 This article presents an innovative predictive maintenance for grinding mills, aiming to enhance operational efficiency and minimize downtime. Leveraging advancements in data analytics and IoT sensor technologies, the approach integrates vibration signal forecasting, LSTM-based fast Fourier transform (FFT) analysis, and convolutional neural networks (CNNs)

[خذ المزيد]

Remaining useful life prediction of grinding mill liners using an ...

2013年11月1日 Knowing the remaining useful life of grinding mill liners would greatly facilitate maintenance decisions. Now, a mill must be stopped periodically so that the maintenance engineer can enter, measure the liners’ wear, and make the appropriate maintenance decision. As mill stoppage leads to heavy production losses, the main aim of this study is ...

[خذ المزيد]

MAINTENANCE IN THE CEMENT INDUSTRY

Maintenance in the cement industry is one of the contributors to the production cost and represent typical 15 – 25 percent of total manufacturing expenditure. Many companies have tried to use standard production methods to control

[خذ المزيد]

Grinding - Metso

Metso has experience with over 8,000 grinding mill installations globally, including manufacturing and delivering the largest SAG/AG mills in the world. Global expertise, local ... Maintenance and repairs for mining. For equipment used in

[خذ المزيد]

Material Use Roller Mill Maintenance: What You

2023年7月25日 Roller mill maintenance will be unique for every operator and depend on the particular materials going through the machine. ... RMS Roller-Grinder is here to assist you with all your roller mill needs, whether you’re

[خذ المزيد]

Grinder vs. Mill — What’s the Difference?

3 天之前 A grinder often refers to a device for breaking down materials into smaller pieces by abrasion, especially for food or coffee, whereas a mill is typically used for grinding grains into flour or for other industrial materials processing.

[خذ المزيد]

DESIGNING GRINDING PLANTS FOR MILL RELINING TO MAXIMISE MILL

While grinding mill maintenance often dictates the length of plant shut down (and thus mill availability and total production) it is rarely made a priority when designing the plant layout. Other important factors such as mill drive selection, other processing equipment, footprint limitations and costs tend to have the biggest

[خذ المزيد]

Predictive maintenance in mining industry: grinding mill case

2022年1月1日 Predictive maintenance in mining industry: grinding mill case study. Author links open overlay panel Ayoub Rihi a, Salah Baïna a, Fatima-zahra Mhada a, Essaid Elbachari b, Hicham Tagemouati c, Mhamed Guerboub d, Intissar Benzakour d. Show more. Add to

[خذ المزيد]

GRINDING TECHNOLOGY OPERATIONS AND MAINTENANCE

The purpose of the training is to Identify and understands necessary known and unknown information towards the completed cycle of the crushing and grinding system. Throughout the course the lectures are supplemented with exercises and case studies, allowing the participants to relate the course material to their cement crushing and grinding facility and as a result

[خذ المزيد]

Minding the Grind: Maintenance Options to Keep SAG Mills

The company simultaneously announced the bearing line and introduction of its new MH Series grinding mill product line in December. The Polymer HSB system will be standard on all its new grinding mills and is designed to maximize grinding mill availability and simplify maintenance.

[خذ المزيد]

Horizontal grinding mill training - Metso

Our horizontal grinding mill maintenance course equips participants with the knowledge and skills required for safe and efficient maintenance of Metso Outotec grinding mills. Training is delivered by our experienced team of in-house certified experts and covers basic knowledge of grinding mill

[خذ المزيد]

Grinding mill inspections - Metso

Equipment failures are always preventable with proper component care and maintenance. To keep your grinding mill running for optimal performance, Metso offers an extended warranty program to expand basic coverage from design and manufacturing to also include installation, operation, maintenance and storage.

[خذ المزيد]- دستورالعمل سنگ شکن مخروطی هیدرولیک بر

- مدل های سنگ شکن معدن

- المعدات الإجمالية للبيع دليل معدات البناء

- من تصميم كسارة الفحم قوات الدفاع الشعبي أو النباتات اليدوية

- مصنع ماكينات كسارة شاوقوان

- مصنع مطحنة حبة في جنوب أفريقيا

- كسارة المورد أجزاء النبات في الإمارات العربية المتحدة

- آسیاب چکشی سنگ شکن ماشین آلات پی دی اف پی دی اف راهنمای

- مخروط محطم الغبار ختم الجهاز

- كسارة فكية كوارتز في البحرين

- سرباره دانه ریز برای فروش

- تطبيق الحجر الجيري المطحون

- كيفية تصميم الرأسي مطحنة

- العمودية مطاحن الأسطوانة محطم الرسوم المتحركة

- الكرة مطحنة المصنعين في الهند

- كسارات حجر القيمة

- مزایای سنگ زنی سطح

- تولید کنندگان سنگ شکن فکی شرکت بزرگ

- مشرف محطم كسارة في اليمن

- خلاطة الخرسانة للبيع في ألمانيا

- غانا كسارة الحجر المركب

- توزيع مطحنة ريمون

- الأصفر هو نتيجة طحن خام اليورانيوم

- آلة طحن الرأس كريغزلست

- ميناء وميناء من الرمال المعدنية من سريلانكا

- كسارة الفك المحمولة من الموردين الهيدروكربونات النفطية

- حيث لشراء خام الذهب المسحوق

- مطحنة الذرة المشتري في أفريقيا

- عمال مناجم نحاس في زامبيا

- طاحونة معالجة الرطب

© Copyright - PETER&X محطم